Our Products

HDPE Telephone Ducts

HDPE Telephone (cable) ducts are made of high density polyethylene (PE-HD) and are intended for mechanical protection of

fiber optic and metal cables. They are used on installations of local and long-distance telephone

networks, cable television transmissions, information transfer networks, etc.

Function:

- serves to form cable conduits for subsequent installation of cables (by pulling or blowing)

- provides a protection for the installed cables

- permits an easy replacement of cables without the necessity to dig the cables out

- increased efficiency in network building

- ease of connecting the ducts with the aid of couplings

- a print indicating length of cables gives information about the length of the cable installed

- possibility of using ducts of different color allows to distinguish cables when several cables are installed in a single trench

- strength imparting the duct compression resistance

- heat resistance providing satisfactory mechanical properties in the temperature range from -20 to +55 °C

- long durability

- resistance to moisture, oil, petrol, rodents and other unfavorable factors that may affect the duct underground

EONN PLAST is a leading manufacturer of HDPE Telephone ducts. We manufacture high quality ducts to provide maximum satisfaction to our clients.

EONN HDPE Pipes (Water Pipes / Telephone Ducts / PLB Ducts)

EONN's High-Density Polyethylene Pipes (HDPE) are made from polyethylene, a cost effective material used for a broad range of piping solutions in municipal, industrial, marine, mining, landfill, duct and agricultural applications. They have been subjected to the most gruelling tests and proven effective for above ground, surface, buried, slip lined, floating, and sub-surface marine applications.

EONN's HDPE Pipes carry potable water, wastewater, slurries, chemicals, hazardous wastes and compressed gases, with the greatest of ease. In fact, polyethylene pipes have a long and distinguished history of service to the gas, oil, mining and other industries. They have the lowest repair frequency per kilometre per year, as compared with all other pressure pipe materials used for urban water and gas distribution.

EONN's HDPE Pipes are strong, extremely tough and very durable. Whether you're looking for long service, trouble-free installation, flexibility, resistance to chemicals or a myriad of other features, EONN's HDPE Pipes will meet all your requirements.

THE UNMATCHED PROPERTIES OF EONN HDPE PIPES

MECHANICAL PROPERTIES

- Long Term Resistance to Internal Pressure

- High Tensile Properties

- Good Flexural Properties

- High Impact Strength

- Excellent Flow Characteristics

- Light Weight & Flexibility

THERMAL PROPERTIES

- Low Thermal Conductivity

- High Thermal Stability

CHEMICAL PROPERTIES

- High Resistance to Chemical Attack

- High Environmental Stress Cracking Properties

OTHER PROPERTIES

- High Abrasion Resistance

- Low Coefficient of Friction

- Resistant to Animal Life

- Low Flammability

- Physiological Harmless

- High Weather ability

THE WINNING FEATURES OF THE ALL-ROUNDER EONN HDPE PIPES

- Excellent corrosion resistance and chemical resistance, resulting in a longer life

- Extremely light weight, hence easy to handle and transport.

- High abrasion resistance

- Earthquake resistance

- High UV resistance to scaling and biological build up

- Emergency connection possible

- High impact strength

- No exhilaration and infiltration, helps maintain the quality of fluid onveyed

- High flexibility combined with strength.

- Excellent water hammer characteristic helps, sustaining surges

- Shifting soils-no breakage

- Excellent flow characteristic leading to significant energy savings

- Smooth inner walls minimises frictional losses.

- Safe for potable water supply.

EONN HDPE Pipes are easy to install, because they are lightweight and come in long lengths. Because of their rapid installation properties and less frequent jointing, they are widely used in applications which include stock watering, irrigation systems, communication, gasses and reticulated water mains.

HDPE Pipes have a proven record for high reliability, as they have been functioning perfectly now for a period of 50 years. HDPE has proved beyond a shadow of doubt that it can provide a long maintenance free lifetime with low whole life costs, when compared with many other materials. In fact, the WSAA Polyethylene Pipeline Code predicts the life of HDPE Piping to be well in excess of 100 years, before any major rehabilitation is required.

EONN HDPE Pipes are normally joined by heat fusion. Butt, socket, sidewall fusion and electro fusion create joints that are as strong as the pipes themselves, and virtually leak free. This unique joining method produces significant cost reductions when compared to other materials.

The performance of EONN HDPE Pipes in mining, dredging and similar applications proves that they will outwear many more costly piping materials while conveying a variety of abrasive slurries. Since HDPE has excellent corrosion resistance and is virtually inert, it does not need expensive maintenance or cathodic protection. It offers better overall resistance to corrosive acids, bases and salts than most piping materials. In addition, HDPE is unaffected by bacteria, fungi and the most "aggressive" naturally occurring soils. It has good resistance to many organic substances, such as solvents and fuels.

Because EONN HDPE Pipes are smoother than steel, cast iron, ductile iron, or concrete, a smaller HDPE pipe can carry an equivalent volumetric flow rate at the same pressure. It has less drag and a lower tendency for turbulence at high flow. Its superior chemical resistance and "non-stick" surface combine to almost eliminate scaling and pitting and preserve the excellent hydraulic characteristics throughout the pipe service life.

EONN HDPE Pipes are produced in straight lengths or in coils. Made from materials about one-eighth the density of steel, they are lightweight and do not require the use of heavy lifting equipment for installation. They reduce the need for fittings, are excellent in shifting soils and perform well in earthquake-prone areas. HDPE Piping resists the effects of freezing and allows bending without the need for an excessive number of fittings. Since HDPE is not a brittle material, the piping can be installed with bends over uneven terrain easily, in continuous lengths without additional welds or couplings.

EONN HDPE Pipes are inherently tough, resilient and resistant to damage caused by external loads, vibrations, and from pressure surges such as water hammer. Even in cold weather, polyethylene piping is tolerant to handling and bending. The high impact strength of PE pipes compared with other materials ensures a greater resistance to the rigors of pipe laying conditions.

EONN HDPE Pipes include carbon black in the raw material and are thus stabilized against ultra violet (UV) light degradation. Our black polyethylene pipes are suitable for installations where the pipes are exposed to direct sunlight.

SPECIFICATIONS

- Manufactured from virgin pipe grade raw materials (PE 63, PE 80 and PE100).

- HDPE pipes have an average life of more than 50 years, under normal working conditions

- Manufactured as per IS-4984, IS-1433, IS-14151, IS-14885, ISO-4427, DIN 8074, ASTM D 3035 and BS-6437 standards in PE-63, PE-80 and PE-100 grades.

- Manufactured from 20 to 315 mm sizes at various pressure rating from 2.5 to 20 kg/cm² (35.5 to 227.5 psi).

- Up to 6 mtr in straight lengths and coils. Higher sizes come in standard and other straight lengths only.

USE THEM ANYWHERE, WITH CONFIDENCE

The major applications of EONN HDPE Pipes are:

- Lift and gravity water supply systems.

- Micro & sprinkler irrigation systems.

- Sewerage pumping and effluent disposal systems.

- Column pipes for submersible pumps

- Electrical ducts

- Ducts for main transmission lines.

- Mining for above and below ground installations.

- Industrial and Chemical usage, to transport aggressive fluids.

- Submerged Pipelines, for cable ducting, water and sewerage.

- Trenchless Construction – for water supply, sewerage, conduits and gas.

OTHER APPLICATIONS

- Marine Outfalls

- Seawater In-takes

- Turnkey Installation Jobs

- Mines De-watering Systems

- Relining of Old Pipelines

- Blowing of O.F. Cables through Solid Lube Ducts

- Slurry Disposal Systems

- Ash Handling Systems

- Industrial Gas and Fume Pipe Lines

- Compressed Air Conveying Systems

- Pipe Line Insulation Cladding

- Dredging Systems

- Marsh Land Drainage Systems

APPLICATIONS CHART

| TYPE AND COLOUR | RANGE (MM) | STANDARD | APPLICATIONS |

|---|---|---|---|

| HDPE Black with Blue Strips.PE-63, PE-80, PE- 100 | 20 to 400 | IS:4984 ISO:4427 |

Portable Water, Submarine Pipeline, other water applications |

| HDPE Black Pressure rating class I, II, III, IV Part I and part II. PN-2.5 and PN-3.2, PN-4.0, PN6.0 |

50 to 315 | IS:14151-1999 (Part I & Part II) |

Sprinkler Irrigation |

| HDPE Black | 63 to 400 | IS : 14333, ISO : 8773 DIN 8077, DIN 8078 |

Sewerage, Effluents |

| HDPE- Yellow, Orange & Black | 16 to 400 | IS : 14885 ISO : 4437 |

Gas Distribution & Conveyance |

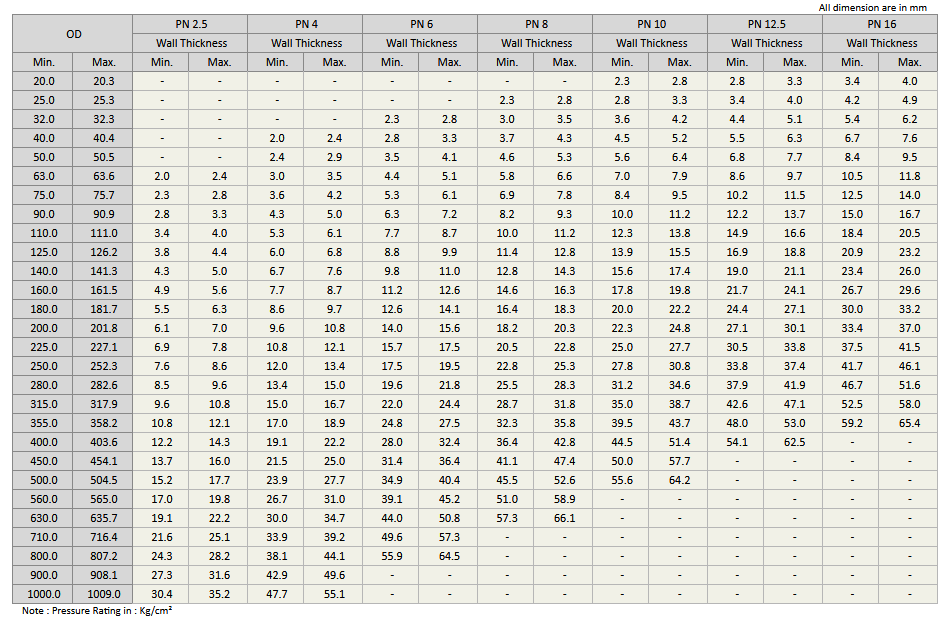

PE Pipe as per IS:4984:95 (With Amendment)

Material Grade PE 63

Material Grade PE 63

Material Grade PE 80

Material Grade PE 100

Material Grade PE 80

Material Grade PE 100

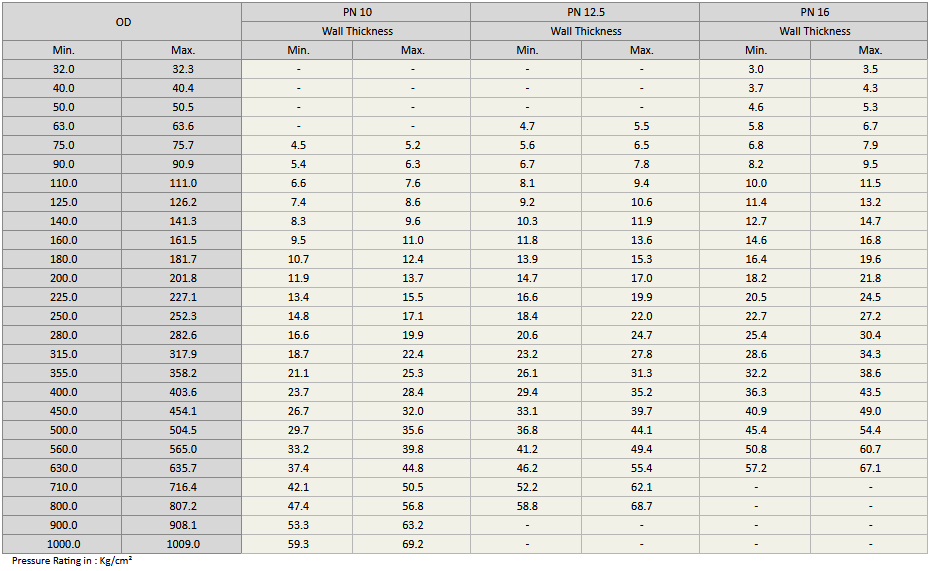

PE Pipe as per DIN:8074-99

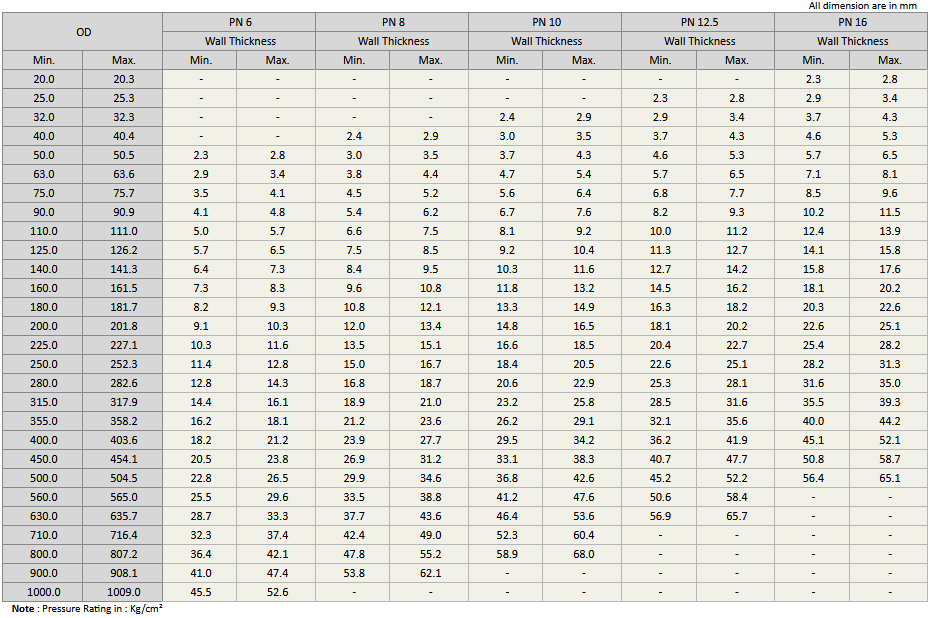

PE Pipe as per ASTM D 3035 (PE 3408)

Dimensions of HDPE Sprinkler Pipes of Material Grades PE63 IS:14151-1994

Designation of Material